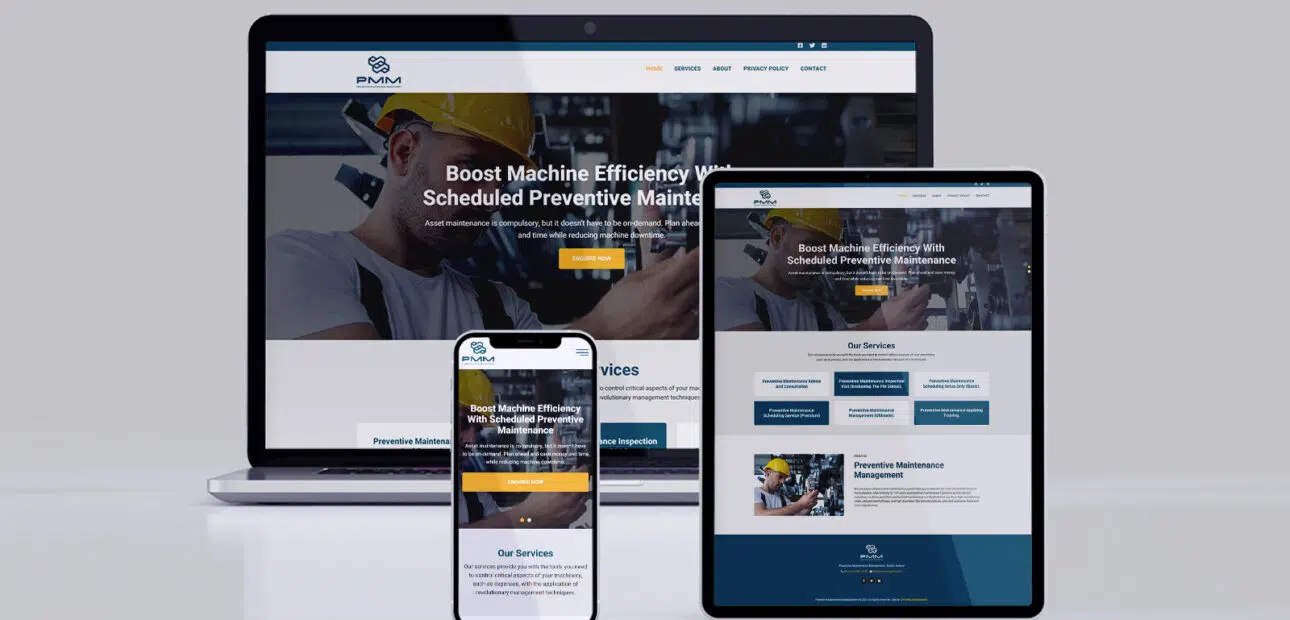

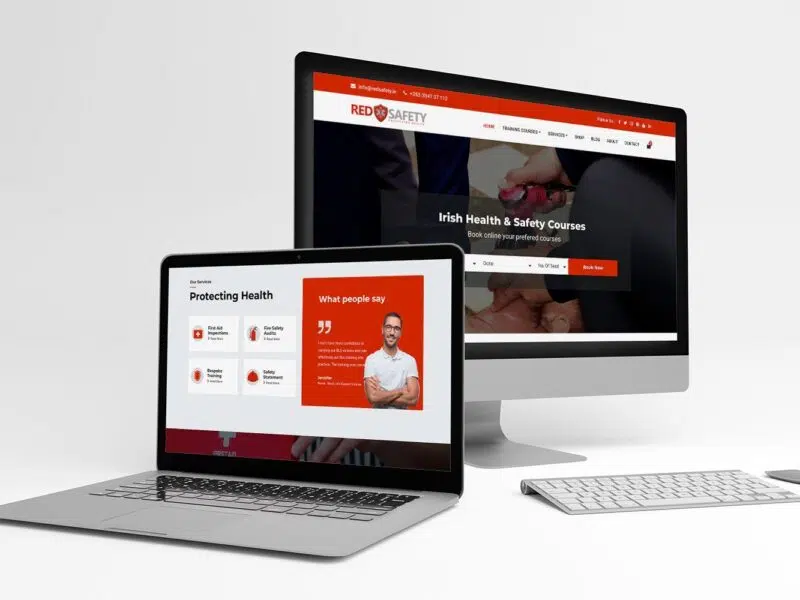

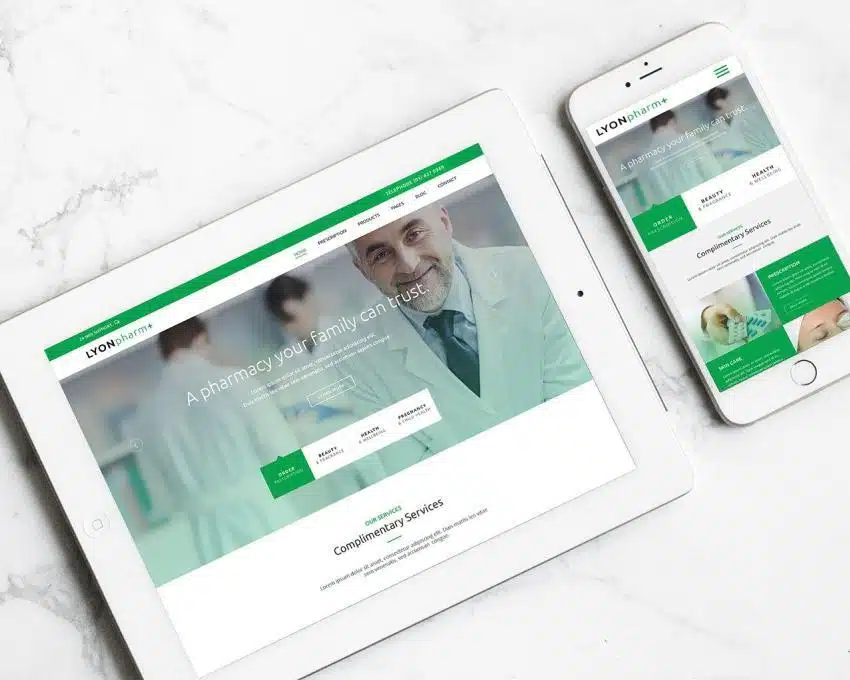

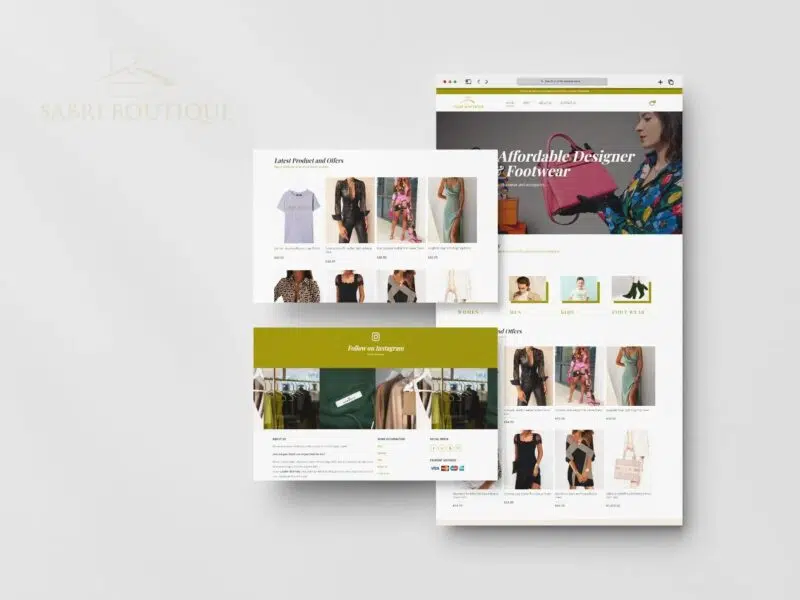

Website Design

Project Information

Category

Website DesignClient

Preventive Maintenance ManagementDate

18 Oct 2021Project Details

Preventive Maintenance Management emphasizes a proactive approach to maintenance tasks, aiming to identify and mitigate the risk of equipment failures before they occur. This strategy involves thorough inspections of machine health, performance metrics, and historical data to establish a structured and systematic maintenance schedule. By focusing on potential issues rather than reacting to failures, organizations can enhance operational efficiency and extend the lifespan of their machinery.

In their previous efforts to implement preventive maintenance, the team faced significant challenges due to a lack of critical information and detailed procedures within their service manuals. This oversight rendered their preventive maintenance initiatives largely ineffective, leading to unexpected breakdowns and operational downtime.

To address these challenges, the organization invested in a cutting-edge computerized maintenance management system (CMMS). This innovative solution integrates all facets of preventive maintenance, including operational workflows, scheduling tasks, monitoring equipment performance, generating comprehensive reports, and facilitating effective troubleshooting. This centralized system not only streamlines maintenance processes but also enhances the overall reliability of the equipment.

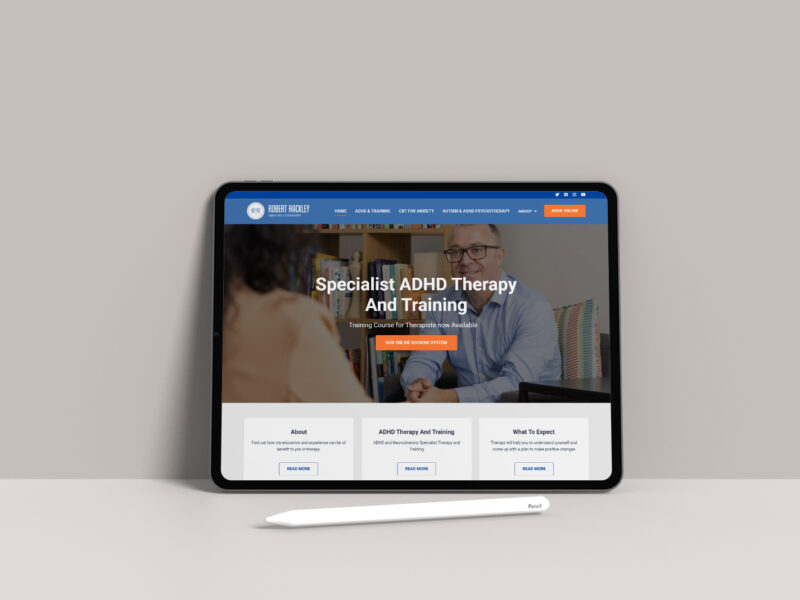

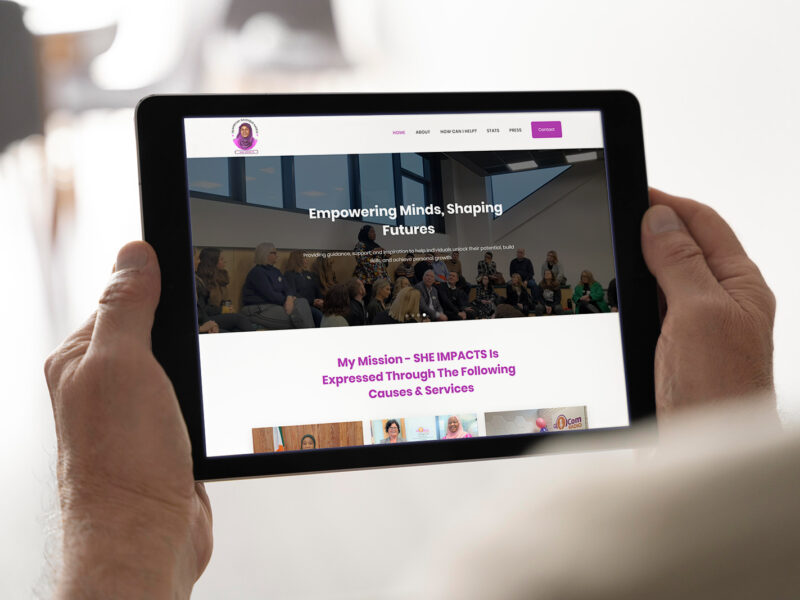

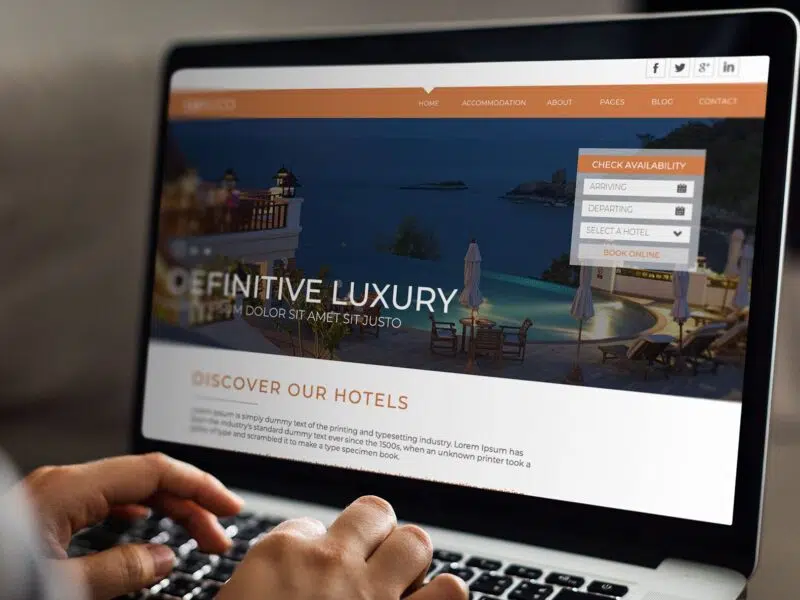

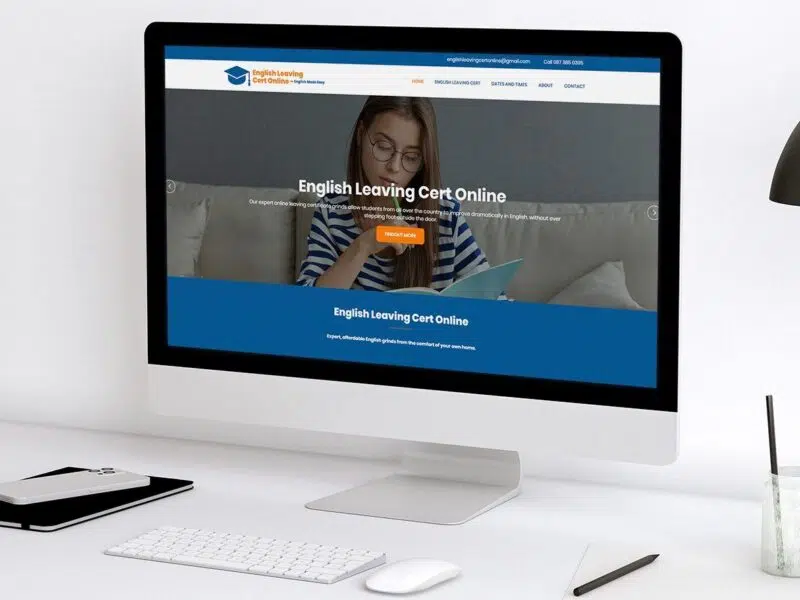

Recognizing the need for a modern digital presence, we embarked on a complete rebranding project for the Preventive Maintenance Management website. In this endeavor, we developed a user-friendly and visually appealing site that effectively communicates the organization’s values and services. The new website serves as an informative hub for clients and stakeholders, providing easy access to vital resources and insights into best practices in preventive maintenance management.

What's inside the pages